ON SUNDAY, May 1, there is a 3½-mile guided walk around Commondale on the North York Moors, looking at the beautiful countryside and at the industrial heritage that we has been featuring here in recent weeks.

Joan and John Roberts are leading the walk entitled An Uncommon Dale, because this isolated area once boasted one of the largest brickworks in the country which became successful when the Esk Valley Railway allowed a seam of fine clay to be exploited.

Stockton builders’ merchant John Crossley took on the brickworks in 1871 and created a hard, deep red house brick. The clay was also found to be acid resistant, and so it was used for sanitaryware of pipes and tiles.

John’s son, Alfred, found he could do more artistic things with the clay, and the British Museum has a delightful rounded bottle made of red terracotta Commondale clay in its collection.

In the early 1880s, the Crossleys sold the brickworks to their manager, Thomas Ness, and Alfred went to the US to lecture on pottery and engineering. Thomas established a head office in Church Row, Darlington, and concentrated on bricks.

Alfred returned in 1892 and became brickworks manager. He died in 1919, and according to his headstone, “he devoted the greater portion of his life to the well being of the community of Commondale”. Consequently, the Alfred Crossley Memorial Institute (below) was built in 1923 out of the distinctive bricks as the village hall.

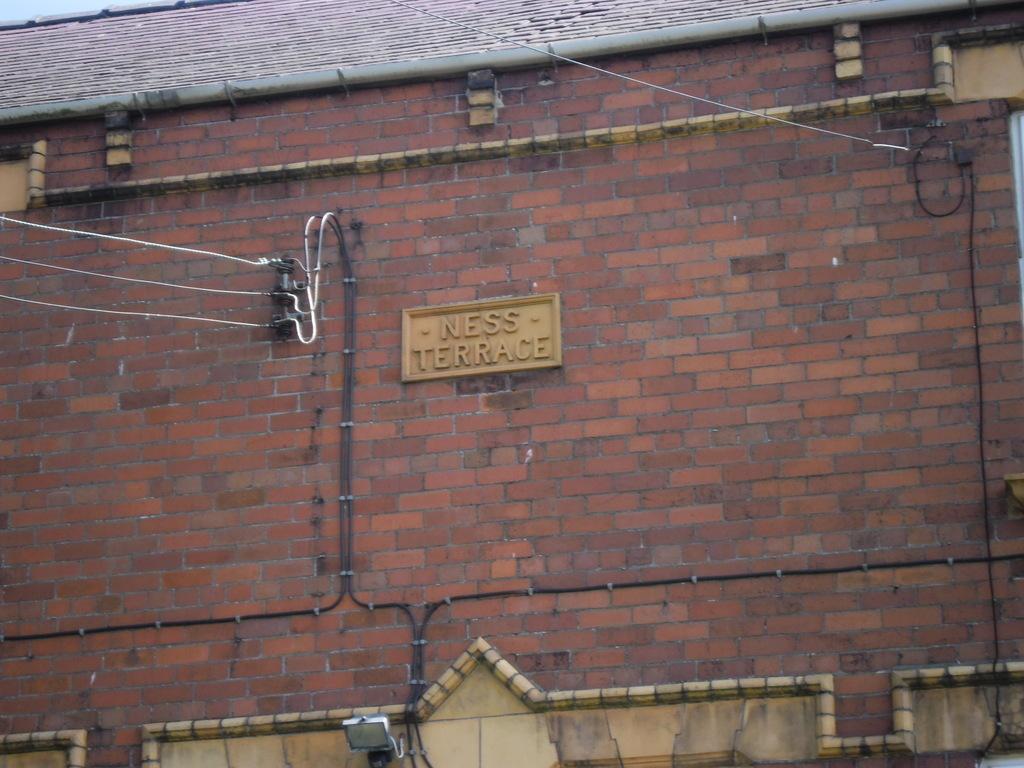

When the Ness family – they are also commemorated with the red brick Ness Terrace – sold the brickworks, a third generation of Crossleys, Percy, bought it in 1927. He, too, had an artistic streak and employed a well-known Tyneside sculptor, Walter Scott, to make garden statues. There is a fine collection of these figures in a Crossley house in Guisborough and in the Whitby museum – do you have one in your garden?

Jo Crossley, the great-great-grand-daughter of the brickworks founder, has in her garden in Melsonby a pair of statues made by Scott. His models were Jo’s father, John, and his sister, Patricia (below).

In 1947, when John had inherited the works, he decided it was too remote. He shut it and restarted his business in Skipbridge, on the edge of Hurworth, where it operated until the 1980s.

Consequently, Hurworth has an unusual Crossley memorial. In the early 20th Century, the brickworks produced “pavers” – hard, orangey bricks to make roads. However, horses slipped on the smooth bricks, and so Crossleys divided the surface of the paver into ten segments, so horses could have more traction. When the lychgate at Hurworth was repaired, Crossleys gave some old pavers to make an unusual road into church (below).

There are bound to be loads more fascinating brick tales tomorrow’s guided walk, which starts at 1.30pm from Sandhill Bank (which is next to Ness Terrace and Potter’s Side Lane). Tickets may be booked through the national park website, northyorkmoors.org.uk or by calling 01439 772700.

“IT has been a fascinating read learning the story of the blue bricks,” says Paul Dobson, referring to the scoria bricks which were made from the silvery-blue slag from the bottom of Teesside’s blast furnaces in the late 19th Century.

READ MORE: THE 150th ANNIVERSARY OF THE SCORIA BRICK!

“In Bishop Auckland, many of the back lanes were paved with them until the mid 1970s when the roads were upgraded.”

Most of the scorias were tarmacked over, but some can still be seen.

Paul adds a cautionary note, pointing out how shards that flake off a scoria can be extremely sharp (above).

The scorias are a distinctive feature of the Tees Valley. It is 150 years since Joseph Woodward, who had a boot warehouse in Priestgate, Darlington, came up with the idea of pouring the molten slag out of the blast furnace into a brick-shaped mould and letting it harden. Until he came along, the slag was worthless waste – the word “scoria” comes from Greek and Latin for excrement or dung, often which had been flung out of the top of a volcano – which was dumped in the River Tees.

Woodward set up the Tees Scoria Brick Company and really hit the big time in the 1890s, when local councils realised his waterproof bricks would be good to replace the filthy soil in the overcrowded yards and back lanes – all the mud, blood, dung, disease and refuse could be flushed off them.

Most scoria bricks are unadorned, but some of Mr Woodward’s moulds produced fancy, interlocking hexagonal bricks. A rare mould pressed the name of his company into his bricks and an even rarer, and probably earlier, mould pressed his own name.

An observant John Williams of Nunthorpe spotted both types of named bricks at the Henry Bolckow Centre in Stewart Park, Middlesbrough (below).

But he, too, adds a cautionary note. “These hard wearing bricks were sometimes the downfall of horse drawn delivery wagons as they were often too slippery for their hooves,” he says.

Frank Ripley has sent in this picture of a fine line of scoria bricks in Back Newgate Street, Bishop Auckland. "I used to call them “engineering bricks” because of their high strength and load bearing capacity," he says. "I’m sure there was a massive railway viaduct between Sedgefield and Stockton made from them, somewhere near Thorpe Thewles, I think." We haven't encountered a structure made of scorias before - are there any?

CONCRETE made from ironworks slag is used to hold up the remarkable pier that juts into the North Sea at Skinningrove – Memories 570 told how an identical technique had been used to build the apartments in the eastern European steelworks town of Mariupol.

But blast furnace slag seems to get everywhere.

“My first job when I left school in 1967 was at Mount Oswald Golf Course in Durham City laying field drains in the wet areas of the course,” says Billy Mollon. “When we dug a trench through the clay subsoil, we put a layer of aggregate on top of the drains to help the water drain away. The aggregate came from Consett steelworks and it looked like the same (steel grey) colour of the scoria bricks, but it seemed to have bubbles in it like Aero chocolate bars – it was called “foam slag”, and was the same material as used on railway tracks where it was called “Aero Ballast”.

“I was told that the golf club got it cheap as one of the golfers worked at the steelworks.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here