AN EU fund is available to North-East companies who want to explore 3D printing.

The fund, part of the European Regional Development Fund (ERDF), is available to Small Medium Enterprises (SMEs) to develop innovative new products and processes suitable for 3D printing or precision layering technologies.

The Innovative Materials via Precision Additive Coating Technologies project, named IMPACT, is being delivered by the Centre for Process Innovation (CPI) and comes via state aid grants, a pot of money of up to €200,000 that SMEs can dip into on a three-year rolling basis.

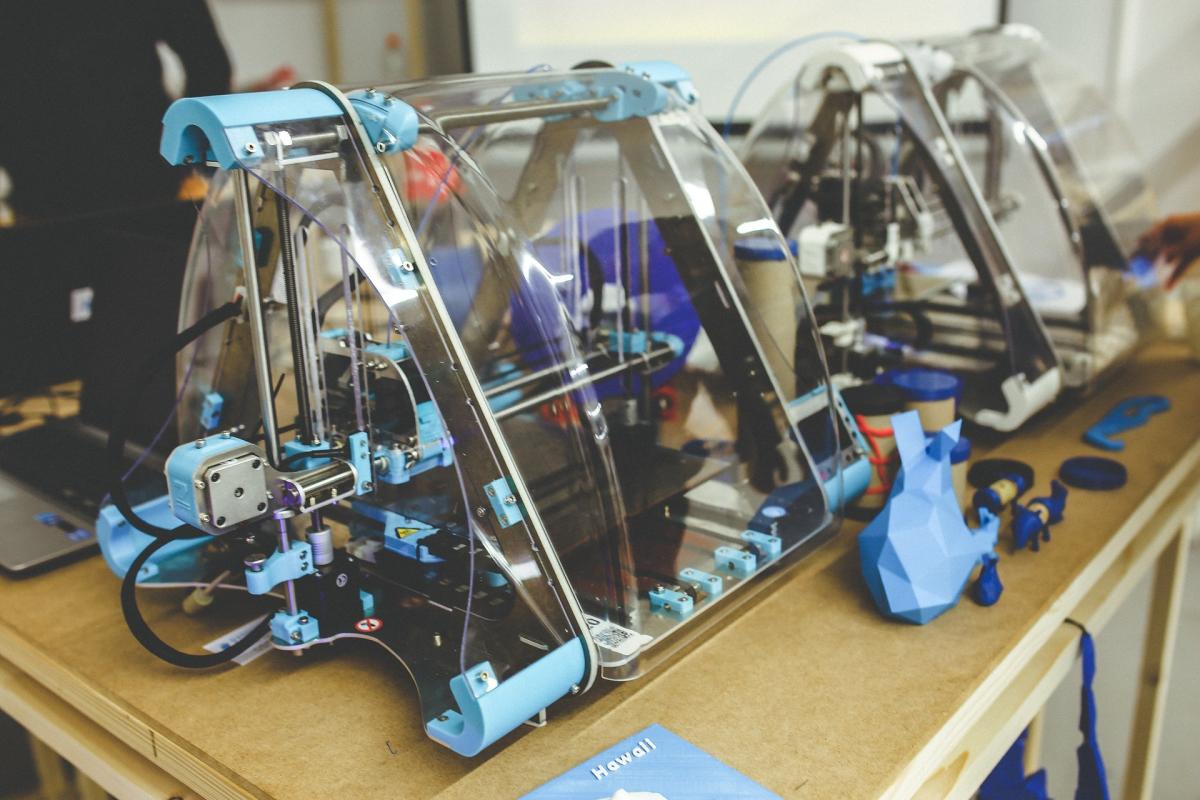

Additive manufacturing, which includes 3D printing, is where materials are added, layer by layer, rather than taken away like in traditional manufacturing.

Instead of focusing on 3D printing itself, the fund enables CPI to provide support for processes that utilise the technology.

This can includes innovative uses of inks, adhesives, formulation for 3D printing and the printing of electronics on flexible materials.

Rachel Squires, business development manager at CPI: “This grant and program for additive manufacturing in the region helps the North-East to be competitive and innovative.

“We have a lot of valuable manufacturing history in the in the region, but it is important that we maintain this though innovation. This is for all UK manufacturing companies, not just the North-East.

"We need to embrace innovation and Industry 4.0 in order to compete internationally.”

Via CPI, the fund is available for businesses in the North-East LEP area and has helped 60 companies in the last 12 months.

Addressing a crowd at CPI, Darlington, Ms Squires urged attendees of the 'Could 3D printing (additive manufacturing) be useful for your business?' event to apply for the IMPACT project funding as there are limited spaces, and an application programme.

"State aid pots are utilised by a number of projects run by different organisations across the regions. Most require some matched funding by the SME, but our program is full funded," Ms Squire said.

Hosting the event were technologists from CPI and Catapult, ttwo organisations focused on "creating real and great economic impact" by helping deliver product development, proof of concept and encouraging company growth.

There are three main benefits of 3D printing, including ownership of the supply chain, reducing costs, and improving components and system performance.

IMPACT project runs until December 2020.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here