INCREDIBLE things can happen in the most unassuming places.

If you have ever driven through the County Durham town of Tow Law, you’ve probably never realised that behind the house facades sits a foundry that has made parts for Royal Navy destroyers.

The story of Bonds is one of near collapse and of survival against the odds. It’s of a business that began in the Victorian age and won the acclaim of Queen Elizabeth II a century and half later.

It is one of expansion and hope that a tradition of highquality engineering providing jobs vital to rural communities can survive global competition.

BondsHold Limited, which now operates the business, runs three foundries employing a combined workforce of 250.

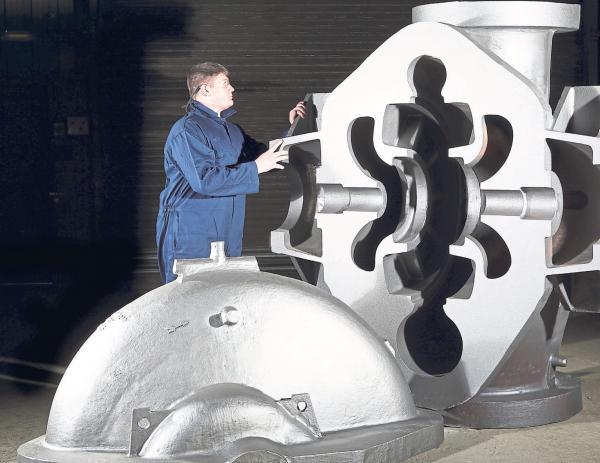

It makes castings for everything from gigantic parts for oil and gas platforms to warship anchors.

In 2011, a former fridge factory in Crook became the latest addition to the group.

The derelict Kenmore site was converted into the first new foundry opened in the UK for a generation. It caters for medium-sized castings from 50kgs to 2,500kgs. It joined sister plants in Tow Law, which dates from 1868 and is capable of making products up to 12,000kgs, and at Alston in Cumbria, where Bonds employ 90 people, making smaller precision castings.

“We are the biggest employer in a 20-mile radius of Alston,” says chairman Paul Duncan.

“Mind you, that needs to be put into context. There are more sheep than people over there,” adds Mr Duncan, who explains how his company has made a habit of pulling businesses back from the brink.

After being placed into administration in 2000, the historic Tow Law site was dramatically saved at the 11th hour by the Steel Group led by Mr Duncan.

The firm acquired Alston’s 60-year old Precision Products in September 2008.

Mr Duncan says: “Once these places close, they close forever.

They don’t tend to come back.

Which is why it was so important that SSI came in and saved Redcar steelworks.

“It’s similar to what we have done over the past few years. If you let a place like a foundry go by the wayside, you lose skills and knowledge that have been built up over generations.

“We have been guilty in this country of letting so much slip through our fingers – industries and factories just left to rot. Ensuring that we keep this business going, and getting to a place where we can thrive in a globally competitive market, is what keeps us going.”

BONDS’ clients include blue chip multinationals such as Statoil, ExxonMobil, Siemens and General Electric. It has been supporting the North Sea oil industry since the 1980s.

Export success has helped the firm’s turnover more than double from £7m in 2008 to almost £17m in 2013 – a ten per cent increase on the previous year.

Mr Duncan adds: “It won’t be a ten per cent rise this year, as things have been a bit subdued in the market, but we predict steady growth and going forward, as enquiries pick up, things will be even stronger as the wider economic picture starts to brighten.”

Crook-based CastTech is now in its second full year of trading.

It employs about 50 people.

Mr Duncan had hoped by now 75 would be working there.

Occupying a ten acre site, with 150,000sq ft of buildings, there is significant potential for additional development.

Mr Duncan adds: “I would never have believed it when we took it over, but we are outgrowing the existing space and looking to expand.” CastTech generated £2.45m sales in its first full year of trading and is on track to make £3.7m this year. The owners have spent £5m on the site, including the purchase of four new furnaces, and they plan to make further investments including a new heat treatment plant, and to recruit more staff.

In 2011, the Tow Law foundry started work on a deal worth up to £4m to make and repair anchors for the Royal Navy. In the same year the company, which exports to 25 countries, was given the Queen’s Award for International Trade.

About 45 per cent of what it manufactures is exported, although the amount of Bonds product that end up overseas is likely to be much higher than that figure as many of its UK-based clients ship finished goods abroad.

“The guys who work here will talk about seeing a casting on a ship with BF stamp on it and how proud that makes them feel,” says director Andrew Shaw, who leads the Cast- Tech business.

Bonds’ exporting expertise, and its ability to turn a hand to a mind boggling range of products have been key to its staying power.

In the nineteenth century, the Tow Law foundry made cannonballs for the military.

There was a time when 60,000 golf club heads at eight shillings a pop were sent every month from the Alston works.

Among the prestigious contracts it has won more recently was the steering gear and propulsion stabilisers for six Royal Navy Type 45 destroyers.

“The basic process of steel casting hasn’t changed much for centuries,” says Mr Duncan, as he points towards a row of finished valves, while the end of the foundry glows with a pleasing orange hue as molten metal is tipped into a mould.

The company’s rigorous testing department ensures that Bonds products are fit to withstand the toughest of environments – from the North Sea to the blazing heat of a power plant.

IN July, the Queen visited Fife’s Rosyth Dockyard to perform the official naming of the 65,000-tonne aircraft carrier HMS Queen Elizabeth.

Bonds made bow castings, stern tubes, stabilisers, and crux castings for the largest warship ever manufactured in the UK.

In terms of staff recruitment the firm’s rural locations are both a strength, which ensures it has an enviably low turnover rate, but also means it draws from a relatively small talent pool. It has developed strong ties with Northumbria University which sees engineering students work at Bonds on placement.

By all accounts, the students find it tough to leave.

The firm recently advertised for a general manager.

As Melissa Duncan, Bonds communications director, explains: “We want to attract local people who bring different skills from other industries and then we can train them in the forging side of the business.

“We have been making castings for about 150 years, so we know how to do that. As we continue to grow at the three sites we have to buy in new skills, such as project management or to improve communications across the sites.

“Our customers are starting to ask us to work with them in different ways on a more project-based arrangement, so we are not simply tracking castings in and out, but keeping sight of the bigger picture as an entire project.”

Mr Duncan adds: “Recruiting the right people isn’t easy, which is why we invest in apprentices.

We’ve also had people join us from foundries in Poland.

The general rule is once people come here they stay. At Alston for example, the average length of service is more than ten years and employee turnover is only two per cent.

“Having the right quality people is essential for a business like ours which depends on us delivery a quality product.”

The group has ten apprentices on its books. This week, it is holding an open day ahead of an additional six apprentices joining the team Mr Duncan concludes: “You have to adapt and take a few knocks. This is not an easy industry and you must be prepared to react quickly to changing customer needs.

“But we are proof that traditional engineering can survive and prosper in this area.”

BondsHold Limited chairman Paul Duncan

Recruiting the right people isn’t easy, which is why we invest in apprentices. We’ve also had people join us from foundries in Poland.

The general rule is once people come here they stay

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereComments are closed on this article