RAMPAGING through the streets, the violence quickly escalated.

Gangs tore buildings apart, their ire squarely fixed on the police.

Daubed in graffiti, a chilling message screamed murder.

“Colin and Dale, we won’t let them get away with it”, the writing warned.

It referred to local youths Dale Robson and Colin Atkins, who were killed in a high-speed car chase.

Their deaths were the prompt for ugly scenes as about 400 people rioted in Meadow Well, North Shields, North Tyneside.

A youth club, fish and chip shop and electric substation were all targeted and burned to the ground.

Police arrested 37 people as they sought to quell the violence.

That was nearly 23 years ago.

Meadow Well has since undergone a transformation, with millions spent to regenerate the estate.

A key facet in that was metalwork and steelwork company Steelcraft Limited.

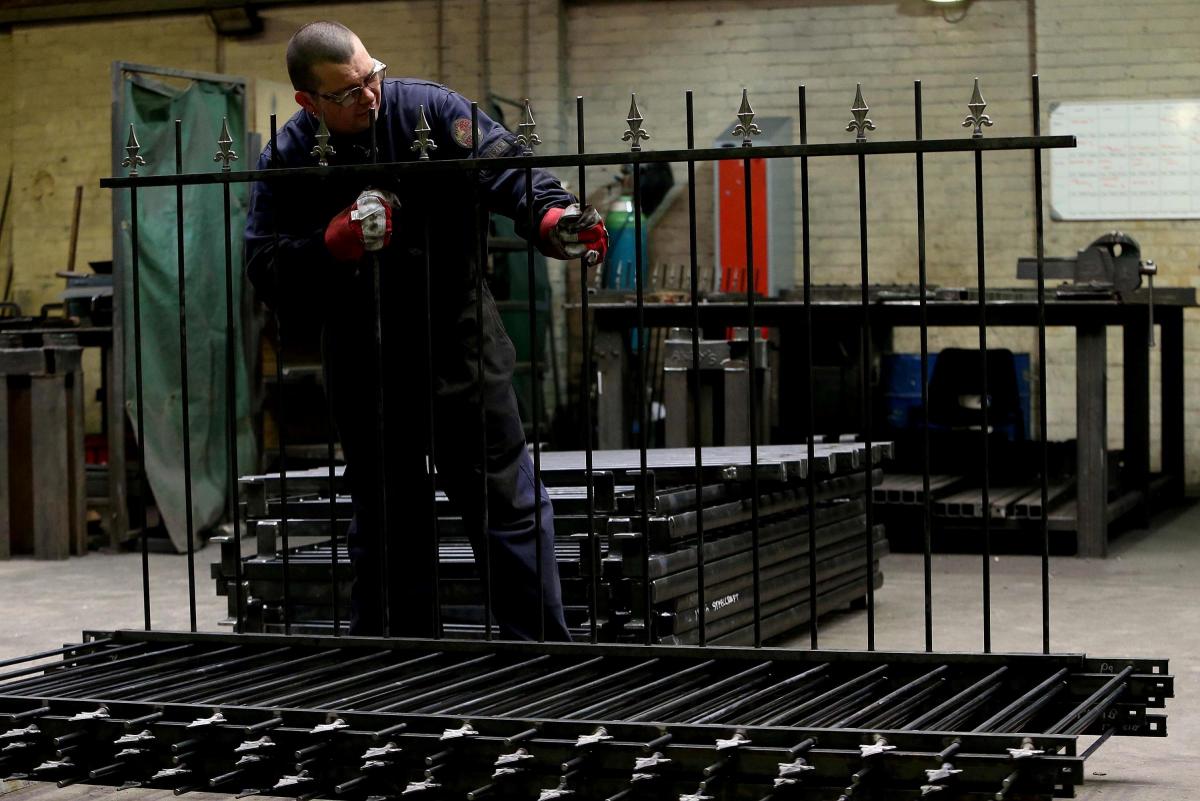

The Chester-le-Street firm makes and supplies railings, gates, fencing, balconies, handrails and balustrades.

As the redevelopment took hold, Steelcraft provided products to brighten the environment.

The third-generation company is this year celebrating its 25th anniversary.

Founded by John Armstrong in 1989, it has carried out work across the region.

Its history starts with security firm Mr Grille, based in Hebburn, South Tyneside.

That company supplied grilles to pubs, local authorities and clubs to protect windows.

Mr Armstrong invested in the firm and in the mid-1990s, it switched to Chester-le-Street to continue its growth.

Based within sprinting distance of the Pelaw Grange Greyhound Stadium, it has since quietly but confidently gone about its business.

Employing 25 workers, it is an old fashioned family-run success story.

Mr Armstrong, who is chairman, still plays an active role in the firm's sales and marketing division.

However, Dave Armstrong, his son and managing director, now runs the company alongside brothers Martin, its production director, and John Armstrong junior, its contracts manager.

His nephew Matthew Rodgers is also a director, with Liam Armstrong, another nephew, working as a management trainee.

He said: “This is a very competitive industry, and we are against China in some areas, but we are a one-stop shop and give customers what they want.

“We give good quality and good service to people.

“We employ 25 people and are looking at ways to grow.

“This is our 25th year and we have a mantra that we are using on that.

“We want to grow 25 per cent with 25 people in 25 weeks to celebrate the 25th anniversary.”

The company works with local authorities and a number of housebuilders, including Barratt Developments, founded by North-East property tycoon, Sir Lawrie Barratt, Taylor Wimpey and Miller Homes.

With Taylor Wimpey, Steelcraft has supported its North-East division for the last five years on the Newcastle Great Park development.

The housing market’s new found growth, fuelled by the Government’s Help to Buy scheme, is certainly playing its part.

Inside Steelcraft’s plant, railings and fencing, covered in their final coat of black paint, are neatly wrapped up and stacked away.

Simple paper notes mark their destination.

Nearby, rows of bars sit at various heights awaiting use.

A radio is drowned out by the grinding and whirring of distant machinery.

Work is constant.

The company operates from the Borders down to North Yorkshire, so activity is naturally high.

It has an order book boasting projects that will be familiar to thousands.

In Newcastle, the Metro’s Walkergate station is being upgraded by Balfour Beatty.

Steelcraft secured the contract to supply handrails and balustrades, bringing it up to modern standards.

Over in Darlington, it carried out repairs and replaced sections of railings in the Denes park area.

It has also worked on signage in Stanley, County Durham, a park entrance archway in Crook, and signs for an estate in South Shields, South Tyneside.

Sitting in his office, as sunshine pours through the window, Mr Armstrong highlights the company’s family ties and commitment to service as key drivers to its success, coupled with the industry’s emergence from the recession.

But he also points to its staff and their continued focus on personal development as major factors.

He said: “We develop everything here and when people come to us they know what they are getting.

“A lot of what we do is bespoke too and that helps.

“There has definitely been a pick up in the last year, with more interest and more enquiries.

“We have got a full order book and are still here swinging.

“A lot of that is down to our work with local authorities, who want to work with us.

“But we are nothing without our people and are putting them through courses to increase their skills.”

The emphasis on growth extends to new products and potential target areas.

He added: “We are looking at new markets.

“If Nissan needed racking for the work that they carry out at their plant, we could do that.

“Similarly, this area has a number of food factories, which all have to abide by strict hygiene rules.

“Our use of stainless steel could come in there too.

“We take the worries off people’s minds and do the job to the best quality.

“When people pick up the phone, they know what they are going to get from start to finish.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here