Recession has had an enormous impact on business across the region and it was those that adapted quickest that prevailed. In this month’s Success story, Bryn Littleton finds out how a light-bulb moment saw a Tees Valley company revolutionise its whole business approach in some of the toughest economic conditions in living memory

NECESSITY is the mother of invention, and there is one Tees Valley company that has more than embraced this old adage.

The recession and its dramatic impact on the construction industry in particular, threatened to derail the fledgling Durable Technologies company before it had established a firm foothold in the lighting controls industry.

However, few companies can have recognised the coming onslaught of recession and moved so decisively to insulate itself against the rigours of the economic downturn as the Hartlepool firm.

The innovative strategy devised by director Alex Carter not only saved the lighting control developer, it was to shape the company’s future success.

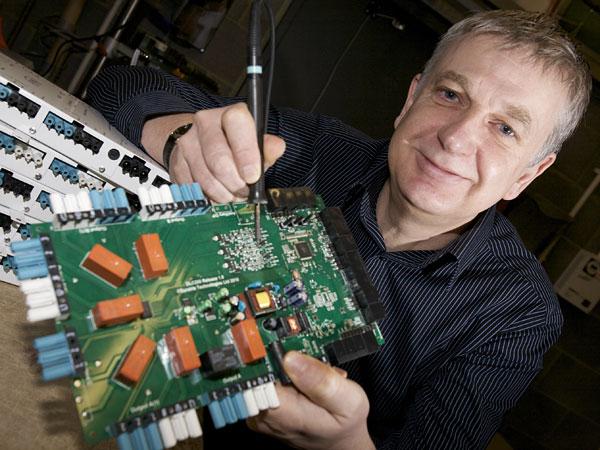

Having established its reputation in the lighting industry with the creation of the DLC1000 control box, Durable Technologies was in the process of refining the device, which controls the brightness, sensors and time-out of modern lighting systems, when the first rumblings of the economic slowdown began.

Faced with falling orders as the construction industry started to falter and cut its cloth accordingly at the start of the recession, Mr Carter realised quickly that the company had to adapt to the rapidly changing economic climate or face possible closure.

“Along with many other firms, we were whacked pretty hard by the impact of the recession on the construction sector and knew pretty quickly that we were going to have to change the way we did things,” said Mr Carter.

What the company did was to revolutionise the lighting industry, upgrading their large, expensive lighting control box for a smaller, easy to install, cost-effective replacement model.

Durable Technologies examined every aspect of lighting control to design and produce the DLC200, which outperforms existing competitor products while reducing installation and running costs, carbon footprint and commissioning time.

“We made the decision to take the cost out of the process,” said Mr Carter. “Any electrician can install our new control boxes, whereas the old version required the sub-contracting of a technician who would be working on an expensive day rate – our products are 50 per cent cheaper to install than most of our competitors.

“The new control boxes are also half the price to manufacture and, while this has helped us grow the business through the recession, we have also been able to pass on the saving to our customers.”

Durable Technologies is on course to crown another amazing year with annual growth for 2011-12 between 75 per cent and 80 per cent.

The environmental impact of products is key in the lighting industry and Durable Technologies has introduced a host of components that can improve energy efficiency by 70 per cent.

Mr Carter and his team have developed the smallest presence and absence detector on the market, a product that is saving firms hundreds of thousands of pounds in lighting bills and massively reducing their carbon footprint.

Absence detection goes beyond the energy savings of presence activation by using a wall switch to turn lights on and off as normal, but with presence detection always ensuring lights are switched off once the area is vacated.

The company’s light harvesting system also constantly adjusts artificial output to augment natural light, giving steady, comfortable illumination while achieving energy reductions of between 20 per cent and 60 per cent Mr Carter said: “We created our control box, our key product, out of necessity.

We knew we needed to change to ensure our survival.

“We have continued to progress with the sensors, the modular plug-in wiring systems – de-skilling a formerly complex process and saving independent contractors on sub-contracting fees.”

The company, which employs five people and is based at the Hartlepool Innovation Centre, has completed a string of high-profile lighting installations across Europe, saving companies a fortune in electricity bills and massively reducing CO2 emissions.

Durable Technologies has installed products at internet firm Google’s European headquarters in Dublin, Aer Lingus’ head office, a string of academies across the UK, including Dyke House, in Hartlepool, and Sirius and Ganton, in Hull.

Another prestigious project, and certainly the most unusual, was installing the lighting controls system in super-yacht Twizzle, an eco-friendly charter yacht that was built in the Royal Huisman Boat Yard, in Holland.

Mr Carter added: “It is a beautiful vessel and was a fantastic project. The builders wanted to make the Twizzle as environmentally friendly as possible and we were delighted to add our expertise.”

The firm is also helping local authorities minimise spending in this age of austerity. The firm carried out a complete revamp of the lighting system at Sefton Council’s headquarters, Magdalen House, in Merseyside.

The 80,000sq ft office facility saw immediate energy reduction of 50 per cent. Meter readings for the building taken four weeks before the work was undertaken and again four weeks after completion demonstrated that the average weekly consumption fell from 11984KW/h per week to 5922KW/h per week, an annual saving of 307,983KW/h, or 167,918kg of CO2 emissions.

It is a far cry from the relatively humble beginnings of a firm that was established on the outskirts of Hartlepool in 2007 by lighting control specialist Mr Carter and his wife, Lorraine.

Mr Carter, originally from Kent, had worked in the lighting controls industry for 20 years and had been based in the North-East since 1991, after taking up what was supposed to be a shortterm role with Consett lighting company Electrak, in County Durham.

“I came up on a six-month contract and never went home,” said Mr Carter, who shares ownership of Durable Technologies with his wife, who is also a director.

“I enjoyed the job, fell in love with the place and that was that.”

He added: “We’re not resting on our laurels. There are a number of exciting products that we are currently working on that are all about further increases in efficiency and reducing the running costs for users.

“The work we’re doing is cutting edge and we’re keeping ahead of the game and, when you consider that we are competing with huge organisations such as Philips and many other international brands, that’s some challenge, but we’re succeeding.”

It is going head-to-head with these established global companies that motivates Durable Technologies to be innovative and continue to expand, enhance its range of products and further build its reputation for excellent customer service.

It has a host of UK patents pending on a number of new products, as well as tailoring its products to be compatible with other manufacturers, enabling Durable Technologies to carry out cost-effective maintenance work on other manufacturers’ products.

“It has been an incredible few years, which culminated in winning the Most Promising New Business and Exporter of the Year titles at the Hartlepool Business Awards in 2009 and 2011 respectively,” added Mr Carter.

“We’re up for another two awards this year, so we’re hoping we can do the double and continue the company’s development and build on our growing reputation.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here