THE shipyards were once the heartbeat of North-East industry.

For tens of thousands of people, they were not only the source of valued employment, but the embodiment of Britain’s status as an industrial leader.

Today, however, the scene has changed.

The days of a booming sector, with massive vessels dominating the regional landscape as they floated away, have gone.

Yes, there are still strong pockets of companies benefiting from their lasting connections to shipbuilding, with engineers and repairers’ order books reflecting their ongoing importance to offshore energy firms’ projects.

But, it can now be argued the North-East is leading another revolution; one focused on electric vehicles.

Sunderland once made a quarter of all of the world’s ships from its famous yards, but it is Wearside’s near 7,000-strong job Nissan factory that’s now regarded as a real industrial powerhouse.

The Japanese company brought production of it all-electric Leaf to Sunderland in 2013, with bosses proclaiming it could make up to 50,000 of the hatchbacks every year, while creating hundreds of jobs.

It blew in on the back of serious momentum.

Back in 2010, the region was crowned the UK’s best connected area for electric cars, thanks to its 300 charging points, stretched from Middlesbrough to Berwick.

Just months later, Wearside’s firm Zero Carbon Futures, led by electric vehicle expert Dr Colin Herron, was launched, saying it wanted to deliver a low carbon revolution to the North-East.

However, to trace the roots of electric vehicle innovation in the region, you have to go back further, and look at Gateshead-based Sevcon.

A majorly important player in the sphere, its products, such as motor controllers and battery chargers, have put it at the forefront of electric and hybrid vehicle technology for decades.

Last week, it revealed increased revenues of £13.3m for the six months between September 2014 and March this year, with profits rising from £594,636 to £627,453.

Although listed on the Nasdaq, the company, which employs about 120 people, including more than half based in the region, was launched on the Team Valley more than 50 years ago.

It is now a symbol of North-East innovation.

But what has ensured such longevity, and how does it expect to continue its growth?

For Matt Boyle, Sevcon’s president and chief executive, the answer is simple; diversity.

The firm operates across purely electric vehicles as well as hybrid machinery, which he says gives it scope to expand.

Mr Boyle said: “The electric vehicle sector is a pretty mixed bag, and is still very niche.

“That is why most of the recent work we have been doing has been with hybrids.

“A hybrid is not a pure electric vehicle because you are also using an internal combustion engine, but it’s not a problem to us because we can do either.

“For the people using the vehicles, they are beneficial because they get rid of their range anxiety.

“People driving a pure electric vehicle have worries it will run out of charge.

“A way of stopping that is to increase the battery, but that is the most expensive part of a pure electric car.

“It’s different with a hybrid because you’ve for the internal combustion engine too.”

Such ability to switch between the two is reflected in Sevcon’s client list.

A quick look shows a South-East Asian deal for advanced motor controllers on four-door hybrid passenger vehicles supported by a previous push into tractor machinery products to target the shift from hydraulic pumps to electric motors.

Known for making parts for Brammo motorcycles and motor controllers for Renault’s two-seater Twizy quadricycle, the firm also previously revealed an agreement to develop and supply controllers to a German company for starter generators on start and stop systems for trucks and buses.

Mr Boyle said industry and agriculture will become increasingly key drivers for Sevcon, which is a recognisable name to regional football fans through its connections with Gateshead.

He added: “For us, it’s all about developing the products what the customer wants in their markets.

“The Far-East is better than the US, which is better than Europe.

“Things like the big cranes, especially in the Far-East, are going hybrid, so there are opportunities there.”

Mr Boyle was speaking to The Northern Echo as the dust settled on the General Election.

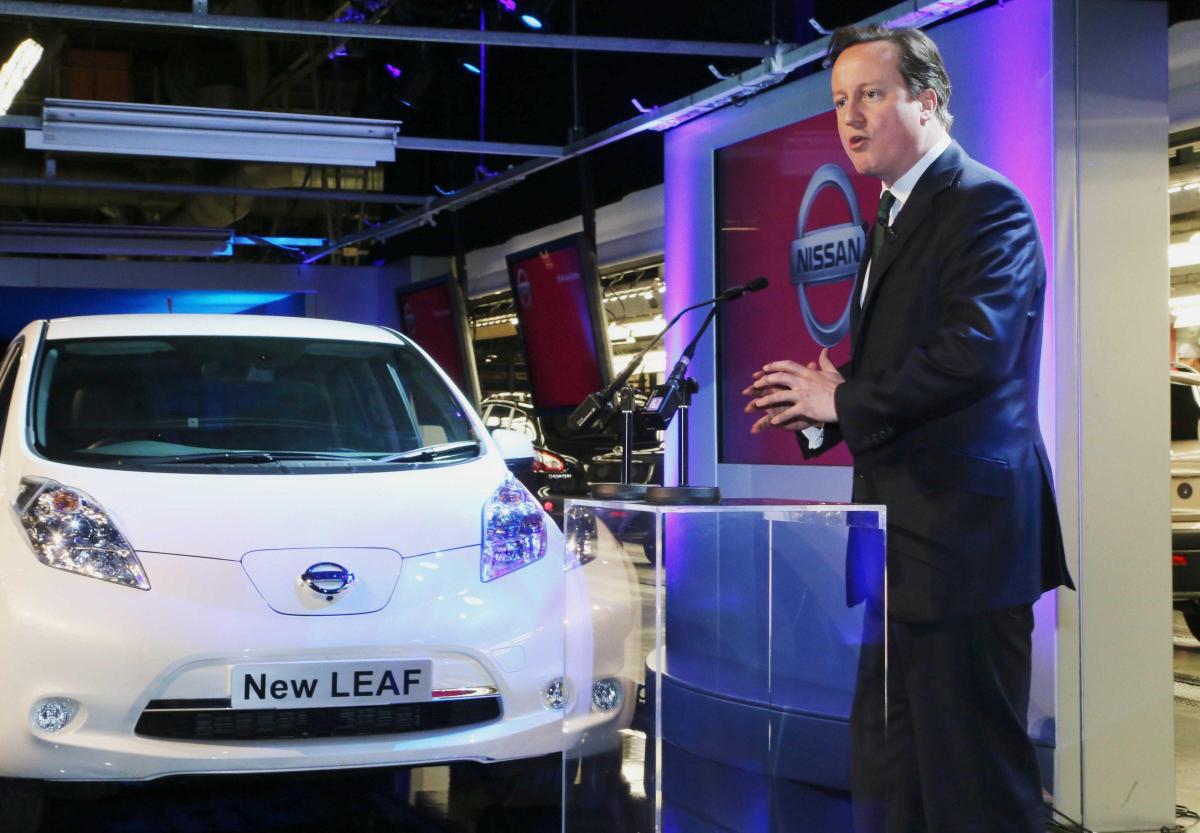

The ballot’s main protagonists, Prime Minister David Cameron and former Labour leader Ed Miliband, both previously toured Sunderland Nissan factory, with the former stepping into Red Rose territory to help launch the Leaf.

Mr Cameron stuck a badge on an electric car while walking the production line back in 2013.

However, Mr Boyle said he hopes the Tories’ election success will deliver a somewhat more substantial impact on the sector.

Asked what the Government should do to help, he pointed to the continuation of existing support, which includes 35 per cent off the cost of a car, up to a maximum of £5,000.

He added: “They should leave the £5,000 incentive in place for pure electric vehicles.

“But what they should also do is support innovation and technology, because they are the future.

“Sticking heads in the sand is no good to anyone.

“The Government must back these new innovations, the engineering and the intellectual property.”

Mr Boyle, who shares his Sevcon duties with time as chairman of the skills group at the North East Automotive Alliance, also warned the region is still short of enough skilled people.

Last month, the company revealed it will take on 20 staff after a £400,000 cash injection from the Government’s Regional Growth Fund (RGF) to develop a range of new controllers.

The firm is in the process of taking on 13 people, from PhD level down to degree-qualified engineers, and is also focused on recruiting apprentices to secure its next generation.

However, Mr Boyle said it still has a lot of work to do to get skilled workers to the region, echoing worries of 2013, when he said the company had been forced to fill posts with Chinese, Iranian and Columbian staff.

Back then, it launched a £200,000 bursary scheme, in partnership with Newcastle and Northumbria universities, to find younger workers.

Now, backed by the benefits of a deal with a German company, he said the time was right to make a concerted effort to increase skills.

He added: “We are now hiring people on the back of RGF and trying to attract these highly-skilled jobs to the North-East and lift the skills we already have in the region.

“How can we do that?

“Well, a very large German company has come to the North-East, the first time it has done so, and if we can give workers exposure to the types of projects it oversees, and the things they need to do, that can only be a good thing.

“There are good opportunities in the near future for us and we need a range of skills in the business.”

PANEL:

North-East electric vehicle milestones:

June 2010: It is announced the UK's first electric vehicle apprenticeship is to be launched in the North-East. Six young people were sought for the apprenticeships, run by Smith Electric Vehicles and Gateshead College.

November 2010: The £7.8m Charge Your Car project was launched to put in place a comprehensive electric vehicle charging infrastructure. Within two years, the North-East becomes the most connected area for electric cars in the UK with 300 points from Middlesbrough to Berwick.

October 2011: Low carbon technology company Zero Carbon Futures, led by electric vehicle expert Dr Colin Herron is launched. “It will bring together all the strands needed for a full-scale low carbon revolution right here in the North-East,” said Dr Herron.

March 2012: Nissan announces plans to develop a North-East facility for research and development of zero-carbon vehicle technology with Gateshead College, which had opened its Skills Academy for Sustainable Manufacturing and Innovation adjacent to the Sunderland plant. Richard Thorold, principal of Gateshead College, said: "This exciting development takes us forward as a centre at the forefront of international automotive and low-carbon technology."

January 2013: Nissan opens a £200m electric car battery plant next to its Sunderland car factory.

March 2013: Nissan Sunderland begins production of the Leaf hatchback. The Japanese company invests £420m in plant and machinery to make up to 50,000 Leafs a year in the North-East, creating 560 direct jobs and about 2,000 in the supply chain.

December 2013: Five new North-East initiatives to develop innovative low carbon technologies are announced and given £900,000 investment through the Regional Growth Fund. Among the companies involved are AVID Technology Group, Seaward Electronics, Teesside University, and Sevcon.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereLast Updated:

Report this comment Cancel