KEITH Miller gets around.

Regularly abroad, he is the seeming embodiment of the ‘have passport, will travel’ mantra.

His trips emit a trove of colourful tales; from swimming in the Gulf with a Russian Fire Authority boss, to armed guards protecting his passage through Nigeria.

But it’s not all holidays and high adventure.

In fact, when he’s away, Mr Miller is negotiating the next stages of his company’s remarkable growth story.

He founded Ecco Finishing Supplies in his bedroom nearly 20 years ago.

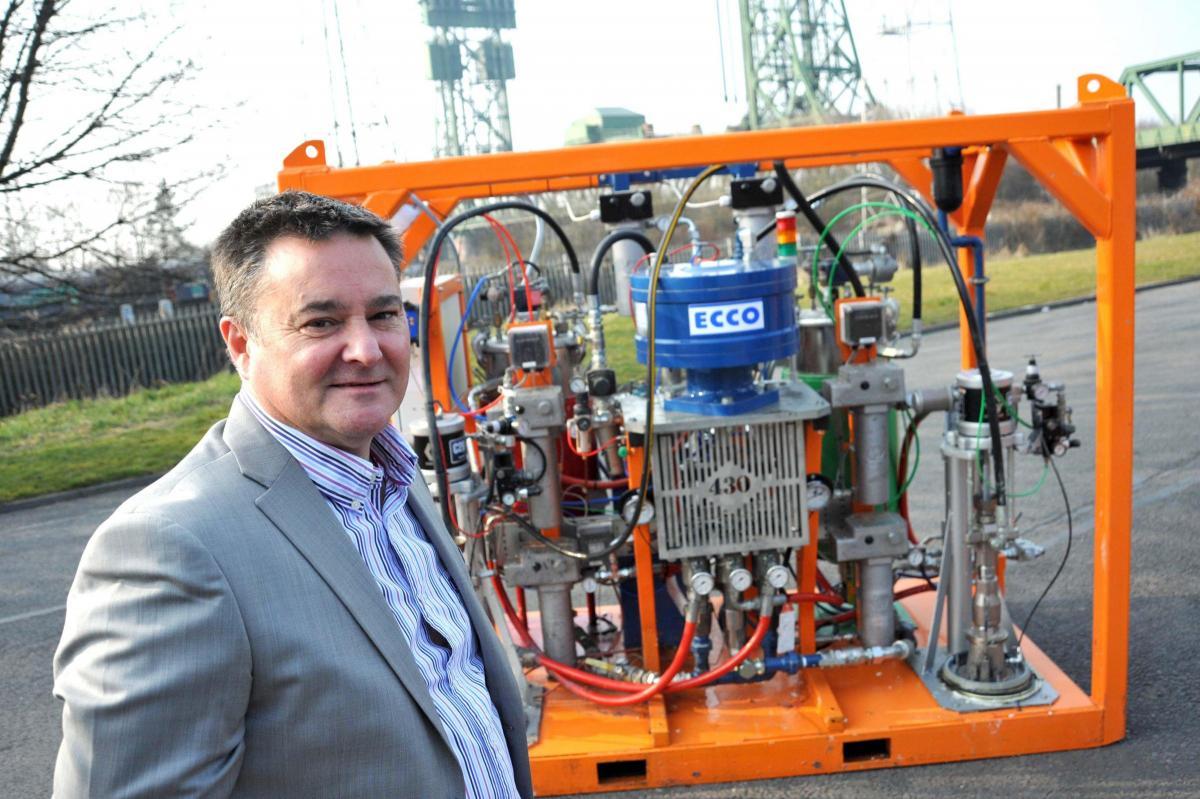

From those humble beginnings, the firm now supplies pneumatic paint spraying equipment, blasting machinery and fire protection, all out of its base close to Middlesbrough’s Newport Bridge, on Letitia Industrial Estate.

A quick look through the order book shows it littered with international clients.

Its passive fire protection machines are used in the offshore energy sector to increase structures’ heat resistance, with its blast cleaning equipment employed to prepare surfaces for painting.

Ecco previously secured agreements to send blast and painting supplies to Angola, with plate blasting parts going to Azerbaijan to work on thick blocks of steel.

Oman-based Tech International is another customer, relying on Ecco’s spray machines to lift heat resistance in steel structures on oil and gas refineries and petrochemical plants.

With that in mind upon my arrival to speak to Mr Miller, I’m expecting yet more progression.

Sitting in an office adorned by pictures of his beloved Redcar Bears speedway team, he has always had positive news to bestow.

So, when I sit down to chat, it’s a little worrying when the conversation starts with a story detailing hours spent up close and personal with members of Dubai’s medical services.

Thankfully, however, any fears over his health are quickly banished.

The trip was, in fact, no more than a formality.

Typically, he was over in the Middle-East on business, and the tests he went through were part of the process to secure the necessary visas and papers to work in the country.

As we talk, he pulls out an identity card, required for site access, as evidence of his endeavours.

He needs it.

He’ll be flying to the destination regularly in the next year, as Ecco continues with plans to set up a joint venture company to secure further work in previously unchartered territories across Saudi Arabia, Iran and Iraq.

Known as Ecco-SPT LCC Manufacturing, Mr Miller said it will be based in the Ras Al Khaimah region, close to Dubai, though he starts explaining the move via his medical travails.

He said: “There were a lot of people waiting to seen by the doctors, and I could feel a lot of eyes on the back of my head as I was called through.

“But I needed to do it for the joint venture, which will help us supply our equipment.

“There are a lot of opportunities for us out in the Middle-East.

“It has gone down well with our customers, and will give us access to places like Iran and Iraq, where we have been unable to do anything because of the embargoes of the Government.

“The company we are working with have their own factory, so we will be using those facilities.

“People are excited about it over in the Middle-East; they love the fact a UK manufacturing company is coming over.

“It will also benefit us being over there to sort any problems that may arise with machinery.

“For a business in the UK, this will be great because we are going to shipping our equipment regularly.

“It will be like a mirror image, they will be working on the same stuff over there, such as the fire proofing.

“We are always looking for growth and this will help us be in a better place to hit our target this year of £6m.”

Ecco’s place across the energy sector is obvious, its order book references such, with a previous £110,000 Kazakhstan deal to supply fire safety products for onshore oil and gas projects, yet another prime example.

His brush with Nigerian military was also the result of meeting clients interested in using its specialist technology and looking at areas to set up a permanent base in the African country.

But how has the company, which employs 16 staff, fared with the falling oil price?

The situation has unequivocally damaged a number of offshore firms, leaving many with no alternative but to thin their workforces amid a downturn in work and project postponements.

In January, The Northern Echo revealed 45 jobs were going at Darlington-based subsea trencher DeepOcean UK, after it struggled against oil prices and what it claimed was a lack of support from the Government over UK renewable energy work going to foreign rivals.

BP also announced plans to cut 200 jobs and 100 contractor roles in the North Sea, with ConocoPhillips, Chevron and Shell forced to make similar announcements.

When I ask Mr Miller the question, he doesn’t even take a moment to reply.

Diversity, he says, will be the key factor, before reiterating industry bosses’ predictions the lull in offshore work will end soon enough, due to the sector’s cyclical nature.

He added: “If the big projects are slowed, the machines come in for maintenance.

“We know the projects will come around again, but by looking at other things, such as the joint venture, we are coming at it from all angles.

“It’s not something we are worried about.

“We have an opportunity to get into somewhere like Saudi Arabia here, which will really help us.”

October marks Ecco’s 20th year in business, with Mr Miller starting it all with a £40 typewriter.

He recoils at my reference to the machine, joking he would like out throw it out of the window, before referring to a new server he’s had fitted to run the company’s computer systems.

But, nevertheless, that now infamous typewriter is a defining image of his journey with Ecco.

A mechanical fitter and latterly, a distributor, for Swedish manufacturer, Atlas Copco, he was involved with selling finishing equipment.

That provided tailor-made experience for launching Ecco in 1995, and he worked from home before moving to Belasis Business Centre, in Billingham, near Stockton, and eventually Middlesbrough.

He added: “I was with Atlas for eight years and left a cracking job, and I thought that if I'm going to do something, I'm going to do it myself.

“So I set up from home using the philosophy that the answer is yes, what is the question?

“The business is built on the fact that stock is available, customers do not want to wait, and that reliability is key.

“We once lost an order in Poland and that was the catalyst for me to think, we could just sit back here and do nothing, or we could become more aggressive and therefore competitive, and that is what we did.

“We've had people come to us and been blown away by our products, they operate like Swiss watches.”

His adventure from one-man start-up may now be over, but Mr Miller will have plenty more journeys ahead.

He better get that passport ready.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereLast Updated:

Report this comment Cancel