PRECEDED by the hum of its engine, a train peers into the light.

Emerging from the station’s darker surroundings, it weaves along a well-used route out of Darlington.

Just yards away, the skeleton of a new building continues to grow, a yellow crane hoisting steel into place.

It’s a symbolic image.

For a town renowned as the cradle of the railways, Darlington is now in a position to continue spearheading another industrial revolution.

The town will become a European leader in medical innovation with a near £60m investment to pioneer research techniques and development.

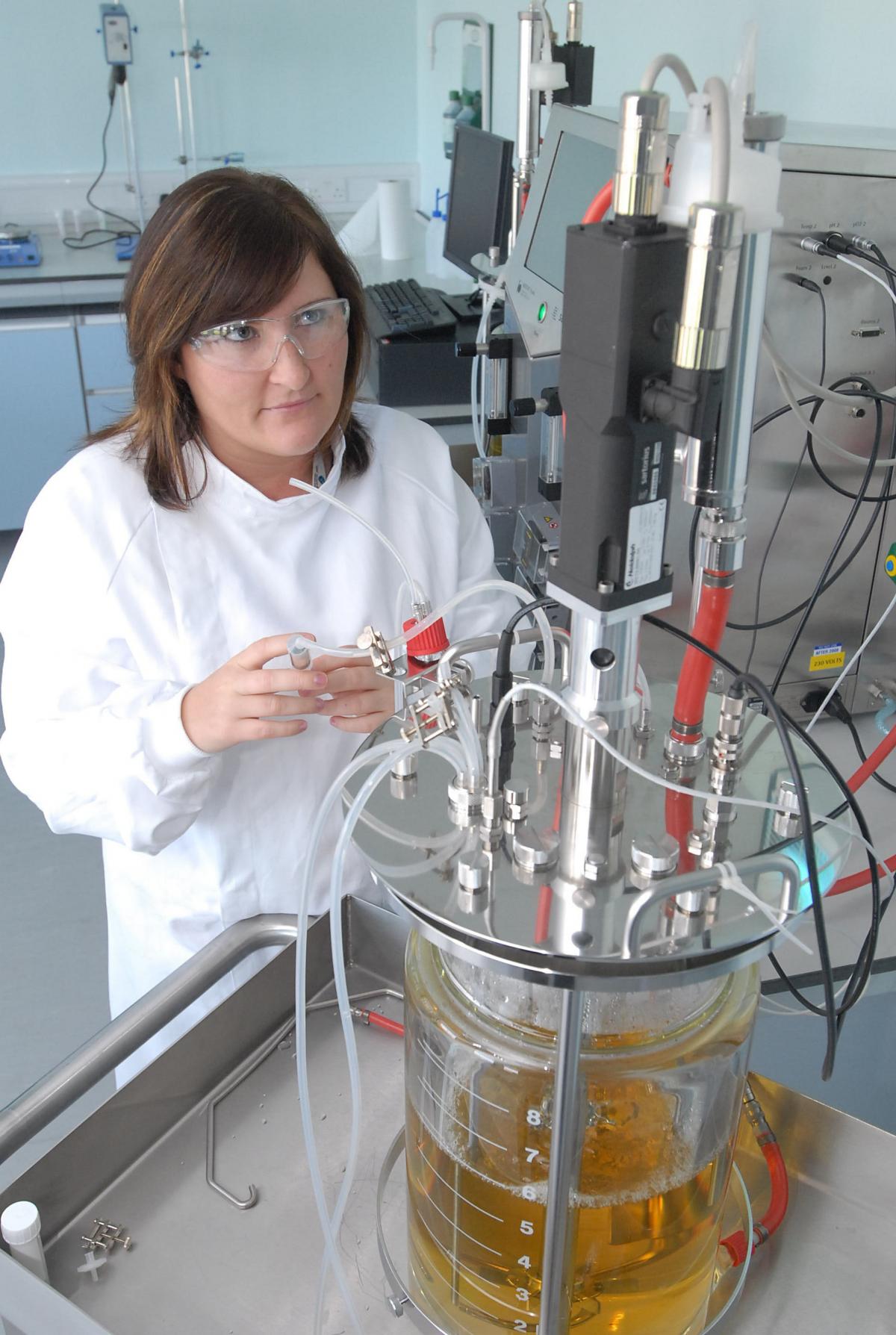

Hailed by Prime Minister David Cameron as a historic landmark, the Centre for Process Innovation’s (CPI) £38m National Biologics Manufacturing Centre will open in 2015.

Funded by the Government’s Office for Life Sciences, it will work on potentially life-saving cures and vaccines.

A £20m sister plant, supported by £10m from Tees Valley Unlimited local enterprise partnership (TVU), as part of the Government’s local growth fund, will follow in 2017.

It aims to revolutionise the healthcare sector by testing and making technology to deliver medicines for specific diseases and patient cases.

Bosses say it will be the first of its type in Europe, with both sites creating scores of highly-skilled jobs and supporting hundreds of construction posts.

Further roles could come to the town if the lab attracts collaborative work and spin-out companies.

Dr Chris Dowle, CPI director of biologics, said the centres could be revolutionary.

He said: “Each individual has their own genome and understanding those helps to better understand how to treat them.

“We can better look at the needs of people and potentially develop individual cocktails of treatment.

“That means rather than getting something which might deliver side effects or not work, we can deliver something that will be effective.

“If the UK is to lead and exploit the significant advances from the investment in biologics research made already, it will need to continue to develop manufacturing.

“This could really start the revolution and herald a new journey.”

Darlington’s place in medical history will come at the expense of the rest of the UK, with sites across the country, including Cambridge, renowned for its scientific reputation, overlooked in favour of County Durham.

Speaking at CPI’s temporary offices in Teesside University’s Darlington campus, as trains flash pass its vast windows, Dr Dowle said the fervour and interest for CPI’s work in the region was intrinsic to the decision.

He said: “With us being in Darlington, it’s a bit like moving from trains to strains.

“There is the sense that the town has a can-do and will-do attitude, and it has a real hunger for new things.

“We went from Scotland down to Kent and each point in between.

“We had a list of more than 30 sites and whittled that down to six.

“Some of those were around places like Cambridge, but, by a good whisker, Darlington was chosen, and for a number of reasons.

“It has good proximity to a lot of universities and manufacturers, such as GlaxoSmithKline and Fujifilm, and there is relative ease for people to get here too.

“That infrastructure and transport made a big difference, and if the council can breathe even more life into the town with its plans for the railway station, then that could open the door for further investment.

“The enthusiasm and will of Darlington Borough Council, Tees Valley Unlimited and the rest of the team put together was very important.

“We haven’t always found it easy to attract people to the North-East, but we are now getting senior figures from around the country.

“They appreciate CPI as a good employer and look as this area as having good momentum.”

For CPI, which employs more than 200 scientists, engineers and support staff, its development in Darlington is simply another exciting chapter in its regional growth story.

By the end of the year, bosses say it will have invested more than £90m into open access facilities for companies to focus on taking products from the development stage to commercialisation.

Across the North-East, its reputation is strong.

The firm has worked with more than 2,000 firms, from large pharmaceutical and manufacturing companies, such as Rolls-Royce, Procter and Gamble and GlaxoSmithKline, which employs 1,000 staff in Barnard Castle, County Durham, to smaller start-ups.

It has also successfully completed in excess of 350 public and private projects, worth more than £300m.

Last month, bosses revealed it was supporting the Darlington-based National Horizons Centre (NHC), which will back emerging industries and could create thousands of North-East jobs.

The (NHC) is a partnership between Teesside University, CPI, Darlington College, Darlington Borough Council and the town’s Centre for Subsea Technology Awareness Training and Education.

The NHC proposals, pledged cash support from the Government’s Local Growth Fund after a TVU bid, will develop industries, including biologics, industrial biotechnology, subsea engineering and digital, ensuring they have skilled staff and facilities to test breakthrough innovations.

The proposed centre will complement the new national business hub, which is being created at the university’s campus.

At NetPark, in Sedgefield, County Durham, CPI’s labs have played a key role in helping PolyPhotonix produce sleep masks capable of transforming the treatment of eye disease in diabetes sufferers.

Funded by £14m of taxpayers’ money, the masks could save the NHS £1bn a year.

Richard Kirk, PolyPhotonix’s chief executive, is unequivocal in his assessment of CPI’s impact on the company.

He said: “Quite honestly, without CPI we wouldn’t be here – that’s the bottom line.”

NetPark’s Printable Electronics Centre received CPI investment, which nearly doubled the premises, with its importance underlined when it became a cornerstone of the Government’s High Value Manufacturing Catapult.

The catapult aims to stimulate growth and support the commercialisation of breakthrough technologies.

On Teesside, CPI has worked closely with the expanding Applied Graphene Materials (AGM), at Wilton, near Redcar, as it targets potential £800m markets.

The company, a spin-out of Durham University, is working on the wonder science material grapheme.

The substance can conduct electricity a million times better than copper, despite being as thin as human hair, and can be used in paints, coatings and lubricants.

CPI was commissioned to build a production plant at Wilton for AGM, capable of making one tonne of graphene a year, with the potential for building up to eight tonnes.

The Northern Echo revealed earlier this year how AGM, now listed on the AIM stock exchange, aims to increase its workforce to 30 by the end of the year, including a business development team covering mainland Europe, thanks to its growing success.

Jon Mabbitt, chief executive, echoed Mr Kirk when talking about CPI’s impact.

He added: “The facilities and support available at Wilton are first-class, and CPI helped us realise the first step of our vision.

“This had never been done before and CPI helped turn it into reality.”

Tata Steel, which employs more than 1,500 North-East workers at plants across the region, has also relied on CPI’s expertise.

It worked with CPI experts to create a thin top coating for its photovoltaic steel roofing to convert sunlight into electricity.

For Dr Dowle, as another train passes the windows on its way out of Darlington, such changing and diverse work is what the CPI is all about.

He added: “You get a real passion for this type of work; it’s the thing that gets you out of bed on a morning.

“It is about making life better for people and improving things.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here