Protecting power cables for global firms, Ellis has come a long way since it sparked into life as the venture of a RAF pilot. Deputy Business Editor Steven Hugill talks to managing director Richard Shaw about its success

A HAIL of gunfire explodes and lights up into the night sky.

Flying over Nazi territory, RAF bomber pilot Arthur Ellis negotiates his Wellington plane way through enemy airspace.

Shells and bullets fizz past the scarred aircraft.

Arthur's trusty Thermos flask also falls victim to the heavy flak.

Mercifully, however, the plane makes it through the tirade, broken but unbowed, and safely back to the UK's welcoming airfields, ready to fight again.

Arthur carried out more than 90 missions during the course of the Second World War.

For a man adept at plotting his course with meticulous detail, it was perhaps obvious he would have the direction of his next career already mapped out.

A skilled plumber, he founded Ellis, formerly known as Ellis Patents, in 1962.

The company began making plastic clip pipes and clamps, with the electricity board a major customer.

Today, energy firms' reliance on Ellis continues, but at a much grander scale.

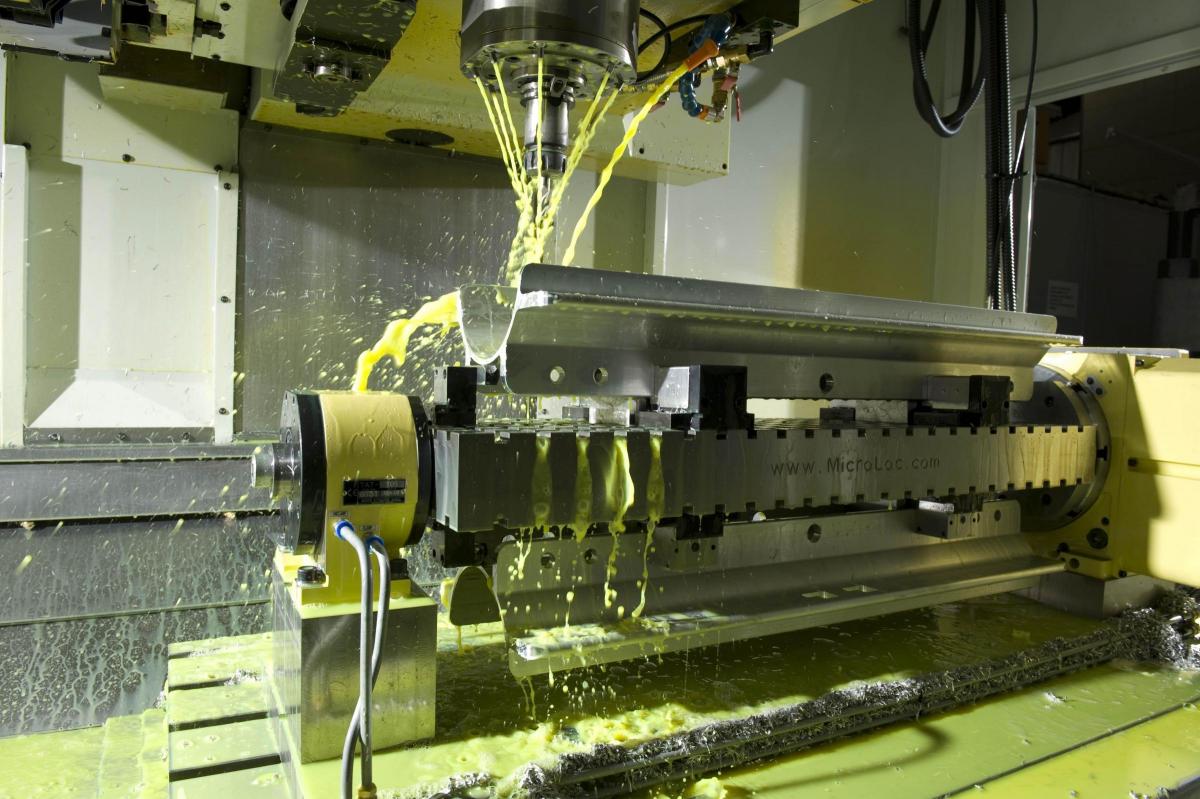

The company, which employs more than 60 workers, is a world renowned maker and supplier of cable cleats to major international projects.

Its cleats, which are all made at its base in Rillington, near Scarborough, restrain cables and can withstand forces generated in a short circuit.

Its order book bestows a plethora of high-profile clients, including Siemens, which has operations in Stockton, Durham City and Newcastle, Balfour Beatty, based in Middlesbrough, Sunderland and Newcastle, and National Grid.

Ensuring the safe running of a nuclear plant in China, Ellis' products are also helping build living quarters on an offshore platform in south-east Asia, and supporting RWE npower Renewables' £1.7bn Gwynt y Mor wind farm, off the North Wales coast.

It won a £1.5m deal to supply thousands of its Centaur saddle cleats to National Grid's London Power Tunnels Project, impressed Ministry of Defence bosses sufficiently to invest in cleats for the first five of its Astute-class nuclear powered submarines, and won a deal to supply products for a project converting coal seam gas into liquefied neutral gas in Australia.

Tremendous growth from a company set up by Mr Ellis in a warehouse behind his house.

The firm has undergone a number of expansions, most recently £450,000 work to add to its headquarters' office space, and bosses expect sales to be more than £7m this year.

Richard Shaw, Ellis managing director, beams when he reveals its successes, which also includes having its products fitted every 600mm in the 55-mile rail tunnel link between St Pancras station and the Channel Tunnel.

Sitting in Ellis' conference room, he reveals a strong passion for the company's future, but retains an equally rich affection for its history.

He said: “Mr Ellis once came back with 99 bullet holes in his plane and they even shot his Thermos flask that was sat by his leg.

“He was a plumber and bought injection moulding machinery, with the company starting off making plastic clips.

“It moved to Rillington in 1974 and by 1987 employed six people, remaining a relatively small operation.

“It was making clips and clamps for customers including the electricity board, and quite a lot of the products we still make today.”

However, in 1987, Ellis' horizons changed, when Mr Ellis retired.

The company was sold to current chairman Chris Calvert and fellow investors at Walkern Victoria Industries, who turned to Ellis after buying injection moulding equipment when a venture into the drinks industry was hit by competition from the US.

Mr Shaw said: “Walkern bought Wrights Drinks, a returnable glass bottle company, but then Coca-Cola launched its two litre plastic bottles.

“They then bought an injection moulding business at the time Mr Ellis was looking for a buyer.

“He put an advertisement out there and they responded.”

From its humble beginnings of red and white pamphlets used to advertise its wares, Ellis' products are now heralded by mythical figures and creatures.

Hues of neon blue, fluorescent red and fiery orange bring its Emperor, Colossus and Phoenix equipment to life, but Mr Shaw says it is Ellis' reputation which makes the strongest impact.

He said: “We are the best in the world in what we do.

“The transformation in the business is incredible and is based on really good products and principles, complimented by continuous product development.

“Our clients are happy and we deliver on time.

“The oil and gas and power generation sectors are our two main areas, but we still do the plumbing products and make about 23 million pipe clips for big outlets such as Plumb Center.

“We are testing our products all the time and absolutely committed to the highest quality, we will always stick to our guns on that.

“We know what we can do and what our competitors are capable of too.”

This knowledge and desire to maintain its superiority has held Ellis in good stead, particularly during the economic downturn.

However, Mr Shaw says it isn't about to rest on its laurels and is keen to strengthen its export sales work and build on its network of global distributors.

He said: “We felt the recession in 2011, a time after a lot of other firms did because of the nature of the projects that we are involved in and the fact big infrastructure projects have a long lag time.

“We are a truly local company, and know we are doing things the right way because of our low turnover in staff.

“Our headcount remains the same and people don't look to leave.

“That is testament to our ethos and the way we operate.

“The philosophy is simple; if you do not grow your competitors will start to nibble away at the sides, so we have to be constantly looking at ways to retain our presence as the market leader.

“One way to do that is continue to develop export sales markets.

“The best way to describe those markets is like an old music hall act.

“You start the first plate spinning and then put more and more up on the sticks, before going back to the first one and making sure it's still going.

“But new product development is also important to us, and if a client says we are not their best customer, we are extremely disappointed.

“Your products have to be first company the distributor pulls off the top of his list, it's no good being the tenth.”

The company also secured Royal approval after the Duke of York visited its factory following a meeting Mr Shaw in Kazakhstan.

The day is still remembered in Ellis' tooling workshop, where a pictorial memento is displayed proudly as a computer screen saver.

Mr Shaw said: “He was on a trade mission in Kazakhstan and came to speak to us about the business.

“When I got back we had just completed the building work on a new warehouse, so I sent him an email asking if he would come and see us what we are doing.

“I never heard anything for a year or so and then out of nowhere I got a phone call from the police asking me about a suitable date for a visit.

“It was amazing, there were officers everywhere on the site looking at everything to make sure it was OK for the visit.

“I later found out that he had made the request to come here.

“It wasn't a case of his people putting a list together for him, he wanted to come here.

“It was a great day, he gave up so much time to speak to everyone and pose for photographs, and it was fantastic for the company to be recognised like that.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here